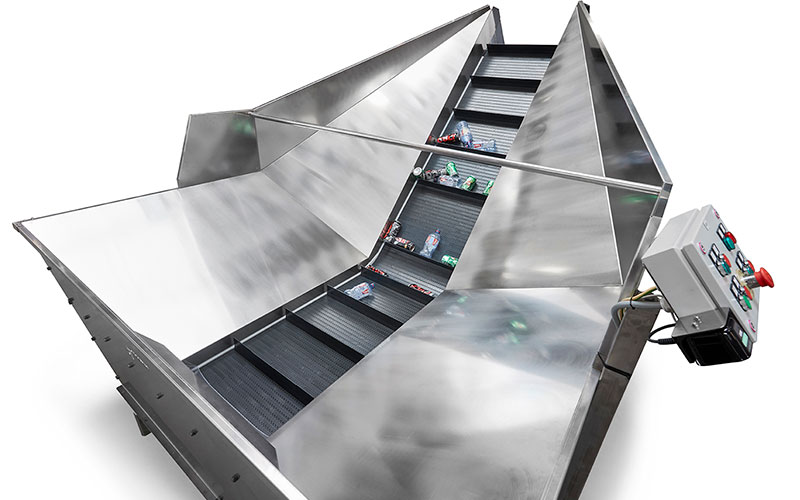

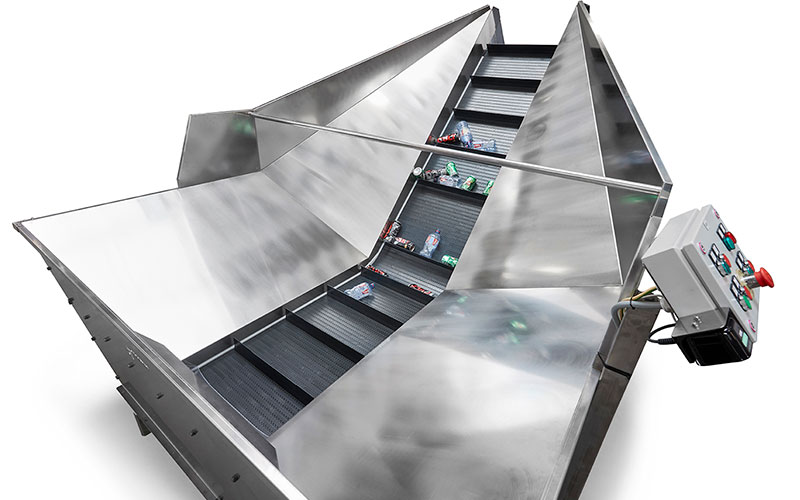

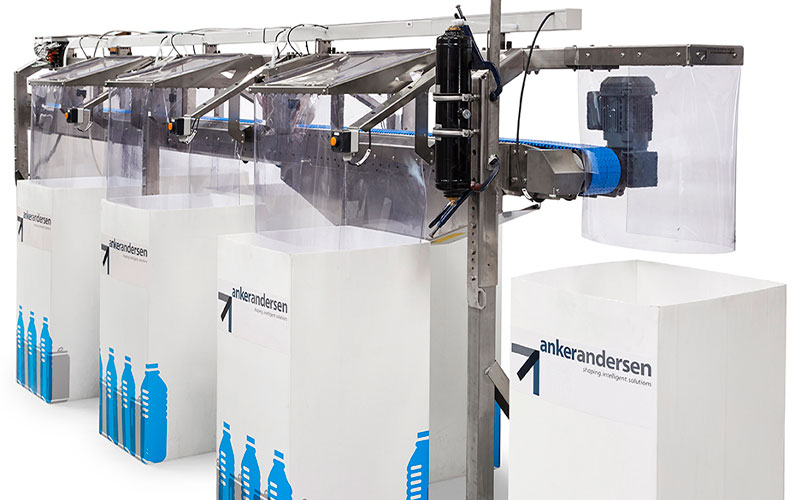

Bulk feeder

Our customized bulk feeder ensures a gentle transport of all container types to the HLZ® system. The bulk feeder is available in different sizes and is particularly suited to feed large amount of containers. The bulk feeder is made of stainless steel as a standard and offers a resistant surface for wet beverage containers with aggressive liquids. The bulk feeder is adaptable to the full range of disc inliners.

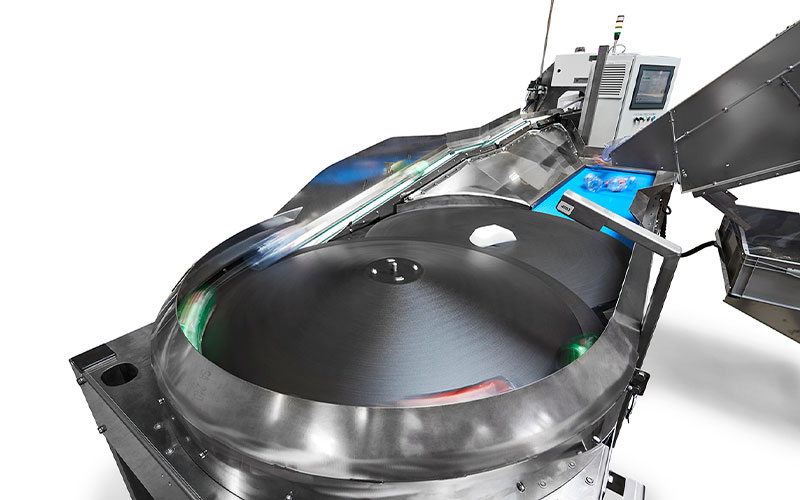

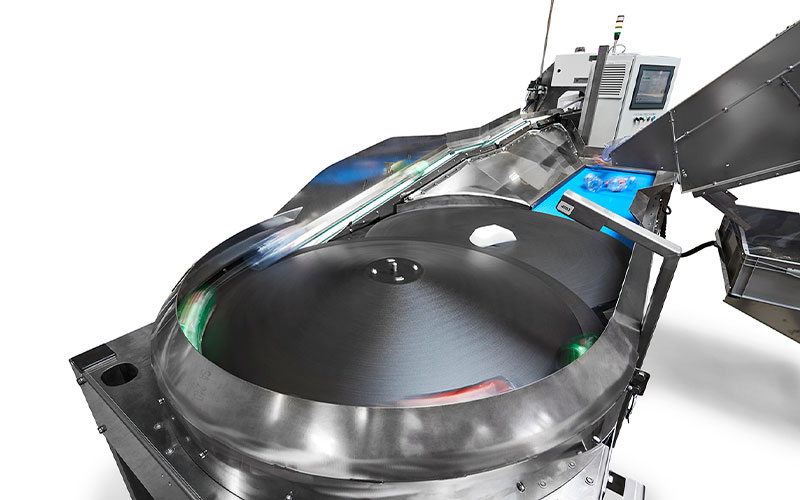

Disc inliner

Our wide range of patented disc inliners ensure an optimal flow with unprecedented speed to the scanner unit. The passive alignment of beverage containers assures high capacity and an uninterrupted counting process.

Scanner unit

The individually customized scanner unit registers bar codes, Matrix codes and security marks with high accuracy and unbeaten capacity in order to determine whether the containers are redeemable. Thanks to the high performance software and our own flexible optical sorting, the precise identification of a wide range of containers is guaranteed. No-reads are registered and handled manually at the no-read station after the scanner unit.

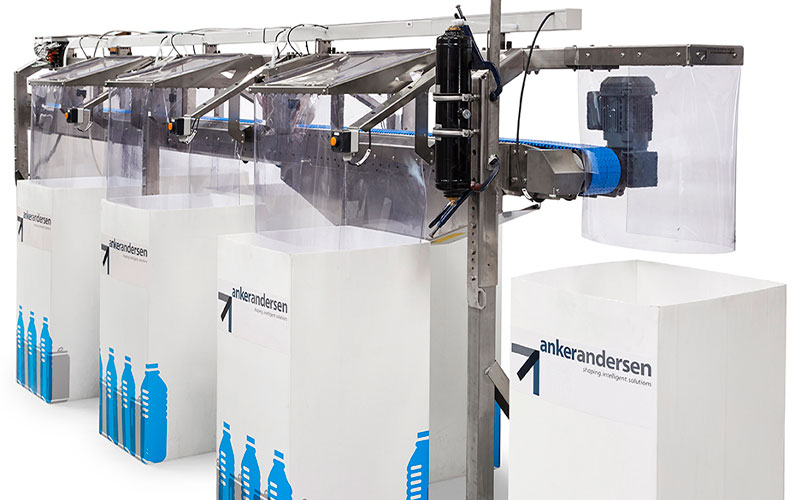

Sorting line

The sorting line provides an optimal transport of all container types. The customized sorting stations ensure that the beverage containers are sorted into the required fractions. Our HLZ® system is supplied with up to 32 sorting stations and provides outstanding accuracy when sorting PET bottles, glass bottles, aluminum cans and Tetra Packs up to 1 liter.